The MHD’s, with fast set-up and low operating cost through customer-inspired designs, deliver maximum productivity. The life of the equipment is long thanks to an innovative hydraulic design, in-house manufacturing advances, and experienced employee craftsmanship. This combination of the hydraulic design and easy maintenance means years of reliable, low-cost operation.

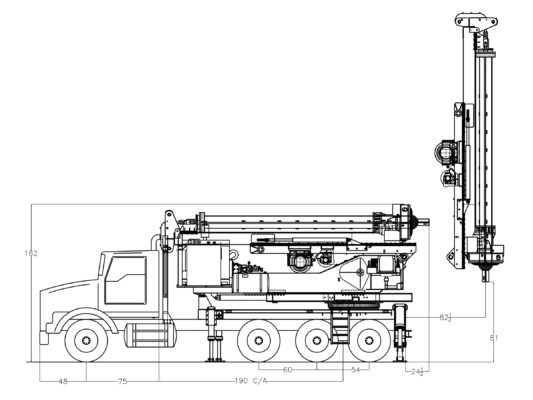

The MHD can be mounted on a conventional truck chassis allowing for quick mobilization, saving valuable time and expense. Such user-friendly configuration means no jobsite assembly, allowing you to be the first to drill and the first to move on to the next job.

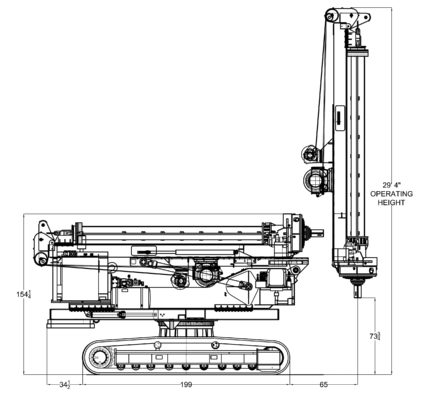

Whether you prefer square or round Kelly bars, the MHD series is available in multiple mast-height configurations. MHD’s can be either truck or track mounted depending upon customer requirements.

We have trucks on site for fast delivery. Call Today.

| TECHNICAL SPECIFICATIONS | STANDARD | METRIC |

| Maximum Pile Depth | 50′ – 120′ | 36.58m |

| Maximum Pile Diameter | 10′ | 3.04m |

| Maximum Torque | 60,000 ft./lbs. | 81.35 kNm |

| Maximum RPM (low) | 18 rpm | 18 rpm |

| Maximum RPM (mid) | 45 rpm | 45 rpm |

| Spin Off Speed | 150 rpm | 150 rpm |

| Crowd | 62,832 lbs. | 280 kN |

| Main Winch | 23,000 lbs. | 102.31 kN |

| Auxiliary Winch | 12,000 lbs. | 53.34 kN |

| Fuel Tank | 70 Gallons | 265 Liters |

| Engine – John Deere 6068 | 225 HP | 225 HP |

“I have used many other brands. I switched because when you work in this industry, you have to buy equipment that lasts. In my opinion, Spiradrill’s are the best.”

-Brandon C.Plaska Line Construction