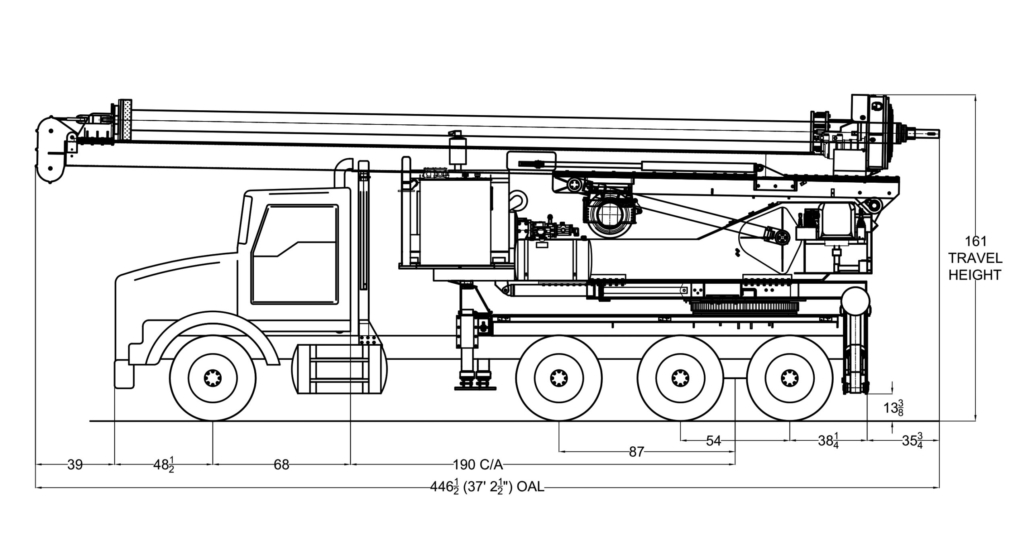

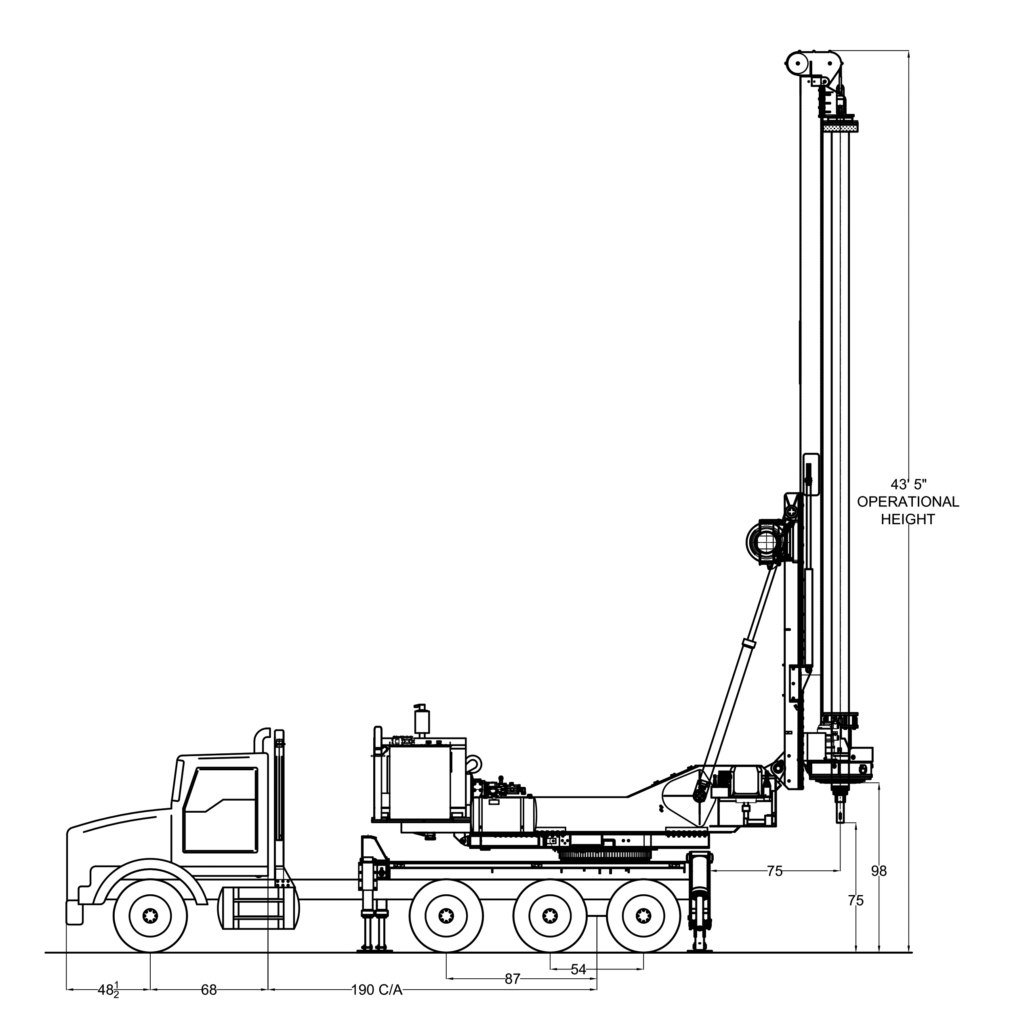

MHD: Medium Hydraulic Drill

Bigger Jobs. Deeper Drilling. Built for Foundation Work.

The MHD is Spiradrill’s powerhouse rig, designed for heavy-duty foundation projects, rat holes, and casing jobs that demand high torque and deep capacity. It offers all the ease-of-use Spiradrill is known for — with added strength, reach, and drilling performance for larger-scale operations.